- Interview

vol.02

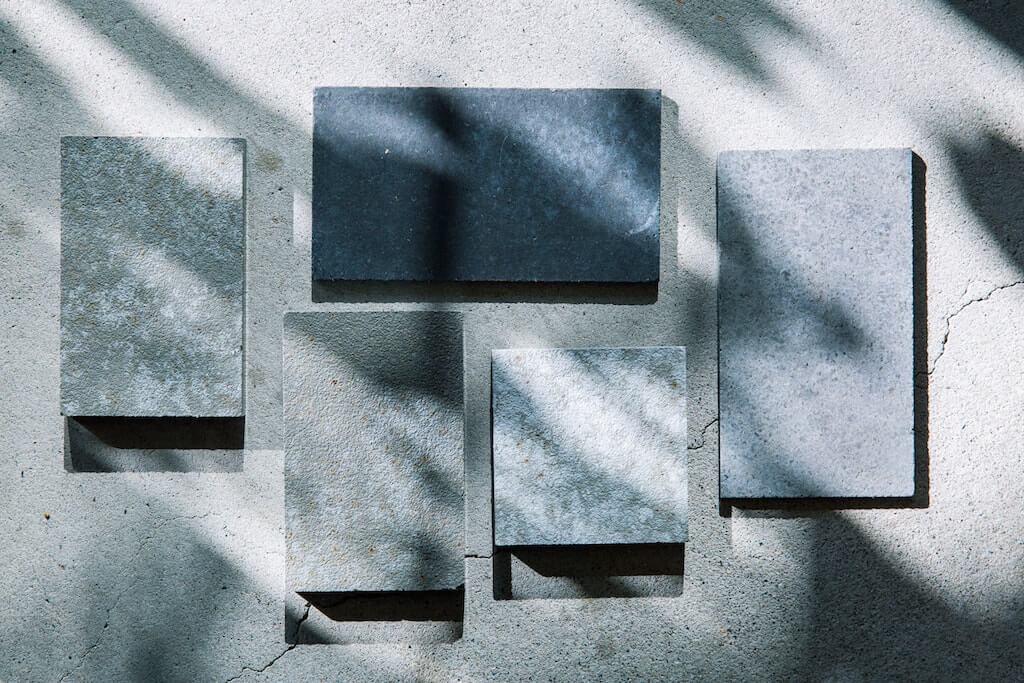

Unique and sustainable. A pure material which shows off the texture of cement, Solido shows how beautiful the changes wrought by time can be.

Dive into Material #2

MTRL KYOTO works to establish connections between creators and material makers by holding various material exhibitions, conducting workshops, and more. As a part of these efforts, “Dive into Material” is a movement launched as a response to the countless creators expressing an interest in learning more about how to use the materials they encountered at an exhibition.

The highly noteworthy subject of our first interview is the material jesmonite. Known as a “chameleon material” due to its ability to exhibit a broad range of textures, jesmonite is used to create a wide variety of three-dimensional works, including art, sculptures, furniture, interior design pieces, accessories, and architecture.

The material we will be introducing in this second edition is Solido, a construction material which shows off the texture of cement.

Originally intended for use in interior and exterior walls, this pure material has been garnering attention on social media for the unique effect it creates. Consumers have let their creativity run wild, developing a range of applications for the material, such as on kitchen counters, shelves, coasters and trays.

- As a tray for tea leaves and other objects.

- For an interior sign.

- [Reference photo] type F coffee interior use example

- type M LAP iron black external use example

- Kitchen counter use example

How can the natural coloration of this material be best put to use?

Kosuke Kinoshita of MTRL Kyoto sat down with designer Masanori Hori and public relations representative Keiko Oda from the company that manufactures and markets Solido, KMEW.

A unique material that shows off the unique features of cement

—The first time I met Mr. Hori was at the workshop for the 3D modeling material Jesmonite, which we covered in the first edition. That was how I found out about Solido, which shows off the unique features of cement. I was interested in the product itself, as well as the environmentally friendly production process, which is why I got in touch with you again.

Mr. Hori: Thank you. I’m looking forward to talking to you today!

- Left: Mr. Kinoshita of MTRL, Center: Mr. Hori of KMEW, Right: Ms. Oda of KMEW

—Let’s dive right in! Solido really emphasizes the unique texture of cement, doesn’t it? Usually, for external walls, siding board designed to mimic natural materials is used to achieve layered textures and colors. Why did you decide to develop a product that bucks that trend?

Mr. Hori: The reason is that an architect told me, “Siding is ruining the Japanese landscape.”

KMEW had been specializing in siding board and cosmetic coatings for roofing materials for many years. Unlike natural materials, “real fake” products do not mature with time for an improved texture and design. However, I believed that applying the materials we had made to imitate natural materials to external walls and roofs was design.

But that architect told me, “Turn over the siding board to reveal the cement, and you’ve got something real.”

We took those words seriously, and decided that, rather than imitating something, we were going to create a product that allows the real texture of cement itself to shine.

—And you went through with it! Solido comes in type F and type M. Could you explain the difference between the two?

Mr. Hori: Type F measures 455mm x 3030mm and is 15mm thick. It’s often used by businesses for interiors.。

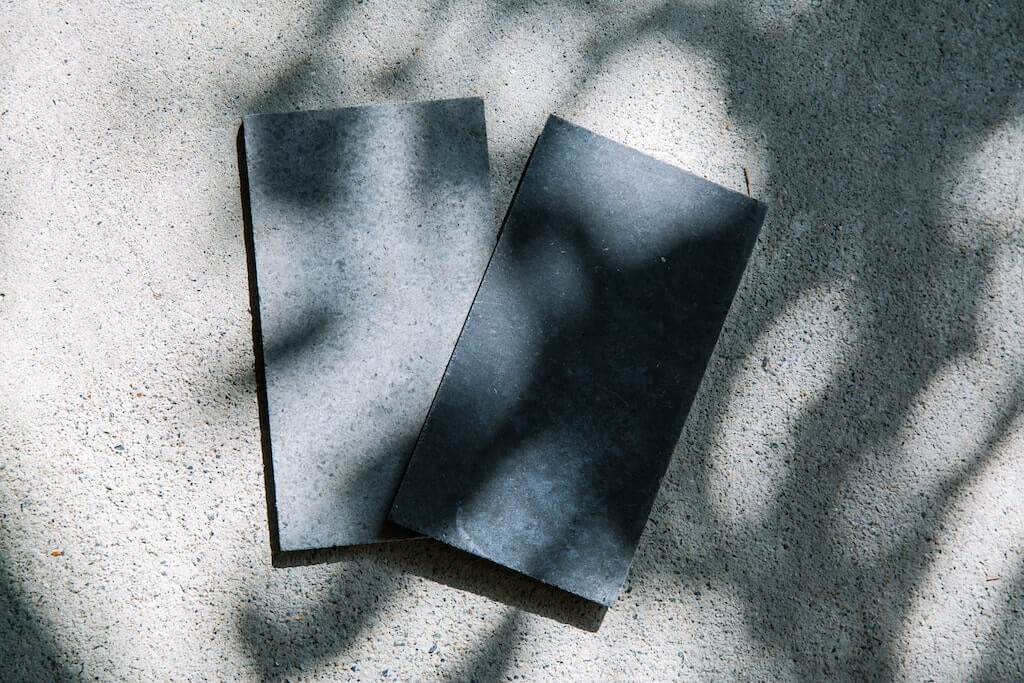

However, type M is 5.2mm lap and 6mm flat, so it’s very thin, but it’s also very strong. It was originally developed as a roof tile, so our workers make it strong enough that it wouldn’t break when used in roofing. Type M comes in two colors: one is a dark color containing iron oxide, and the other is the natural color of cement.

- typeF coffee

- Iron black

—Both colors have a non-uniform texture and a “just right” handmade look.

Mr. Hori: Thank you. One of Solido’s distinctive features is that the surface is untreated, so the surface and the cut edges have the same texture.

When cut with a diamond cutter, the cut edges have a rough texture, and when cut with a single cutter (large scissors used to cut straight roof tiles), it has a natural texture that looks almost like it’s been broken by hand.

- Edge cut with a diamond cutter

- Edge cut with a single cutter.

—Many people think of cement as a man-made material, but it’s actually made from natural materials, isn’t it? When cement is typically made to be uniform, it takes courage to purposely create unevenness and distortion. How is Solido made?

Ms. Oda: The basic ingredients are cement, pulp, and water. We also add additional fibers like polypropylene to strengthen the materials. We mix the materials together and subject them to high temperature and pressure in an autoclave, and you have Solido.

- Raw materials for Solido type F coffee. S material is pulverized defective product. This is added to increase cement grain size and strengthen the material.

—How do you achieve the desired texture?

Mr. Hori: When the material is treated in the autoclave, the water vapor rises to the surface, and this causes fading, creating a raindrop pattern. These patterns do not form uniformly, so each piece has a slightly different texture, and even when the material is new, it looks like it has been aged many years. I like to call it an “industrialized natural product.”

- [Reference photo] The Solido production process

60% recycled materials Sustainable manufacturing that’s kind to the environment

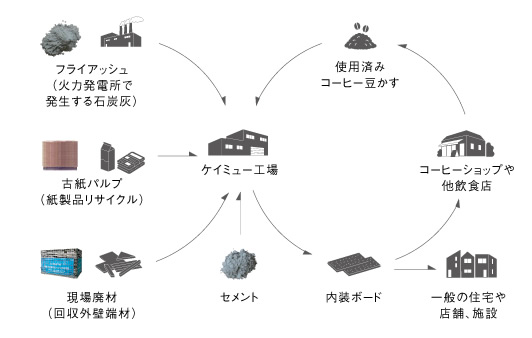

—In recent years, more and more people are beginning to take note of the Sustainable Development Goals (SDGs) set by the United Nations. Solido is a sustainable material made using a cyclical manufacturing process.

- By utilizing a cyclical manufacturing process, we are able to minimize our impact on the environment.

Mr. Hori: Solido is made from 60% recycled materials. We use all kinds of industrial waste products, such as coal ash from power plants and pulp from recycled paper.

Ms. Oda: We have been recycling waste products for our other products for some time. However, with the current trend towards reducing industrial waste, we have put an increased emphasis on recycling with Solido.

Mr. Hori: In type F we have a product called type F coffee, which is made by mixing coffee grounds from cafes with layers of cement. One of the cafes that has provided us with coffee grounds is using the product in their interior. While cement usually has a cool look, this product’s warm coloration makes it a good match for wooden or warm, light interiors.

- With type F coffee, you can actually see the brown specks in the cement.

—Mixing coffee grounds with cement, what an interesting idea!

Mr. Hori: The coffee ground mixing process is done by hand by experienced craftspeople. At first it was quite uneven, but now they’ve got the hang of it and are able to sprinkle the grounds in a way that’s “just right.”

We are also experimenting with new types using pulverized rocks and rice husks.

—It’s wonderful how you’re able to tell a story with your construction materials by using different kinds of industrial waste products.

Mr. Hori: We wanted to use a type made with rice husks for antenna shops in rice producing regions, so now we’re working on actually developing the product. If we’re able to use waste products from that region, it will really add a sense of originality.

We wanted to reflect business owners’ wants and needs, and we’re hoping that Solido can provide those interested in recycled materials with the opportunities they’re looking for.

Purposely leaving room for interpretation

—There’s one more thing I’ve been wanting to ask you, Mr. Hori. Is Solido’s PR important to you as a designer? One thing that stands out about Solido is the attention to detail.

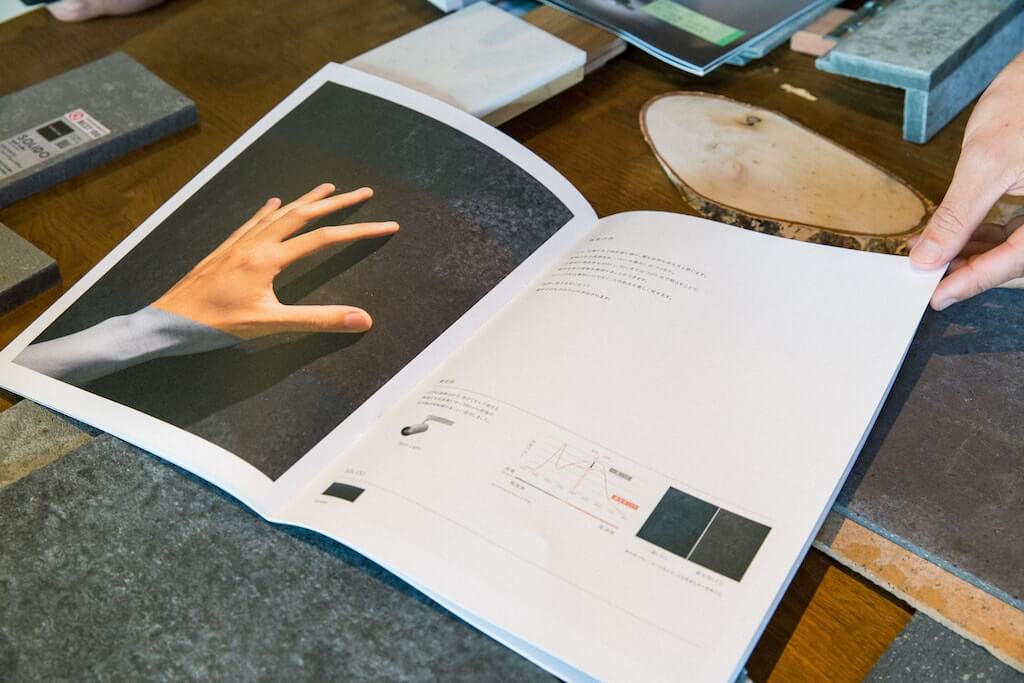

Mr. Hori: That’s right, Solido leaves designers a lot of room for interpretation. We were inspired by “The Pine Trees” folding screens painted by by Kano Eitoku. You get a sense of the intentionality of the blank spaces in that work.

For Solido, as well, if you think, “What should I make of this cement?” that’s the start of a conversation. That’s why in our catalogs and exhibitions, rather than plastering our brand name over everything, we like to leave just the right amount of pleasing blank space.

- A collaboration catalog between Solido and an architectural lighting maker. It’s more conceptual than our previous stuff.

—Wow, how cool! As a piece of reading material, it really draws me in. However, I can see how it might be a little too conceptual for a product catalog.

Ms. Oda: Right. This is something new we’re trying out.

—But I think it’s a really genuine initiative. We list specs and other basic information in our conventional catalogs, and show the Solido concept with the creative power of photos and words. Even in the architecture field, this kind of approach is pretty unique, isn’t it?

Mr. Hori: I haven’t seen anything like it before. While catalogs are generally made to sell products, with this, we’re aiming more to share our concept.

Mr. Hori: Rather than just marketing Solido as a product, we want to share it as a material, and our approach to communication via our website and catalog also leaves the viewer some room for interpretation.

The collaboration we’re doing now is an experiment in taking this approach to the next stage. We wanted to show that we, as producers, want to collaborate with designers and creators, and while it may be subjective, we wanted our catalog to be an embodiment of the moment you see one of our products and think it’s beautiful, and our passion for expression.

—For the architectural photos we have to make the room appear large, so you don’t normally see the contrasting grains of the materials. That’s what makes the methods we’ve used to show of Solido so appealing.

Getting things “just right” with technology and experience

—So far we’ve talked a lot about the texture and concept. But I wondered what difficulties you may have faced in regulating the quality of an industrialized natural product. How did your workers react?

Ms. Oda: As you suggest, the early stages of development were challenging. Our company had established a practice of producing uniform products, so even if we said, “We’re going for unevenness,” or “We want to make each product unique,” many of the employees manufacturing the product didn’t understand.

At first we let anything slide, but we found that some of the products had too much fading, or were too dark. We decided we wanted to maintain some level of consistency in our products.

Ms. Oda: It’s easy to say, “We want to get it just right,” but what exactly is “just right?” It’s difficult to measure. After much trial and error, we realized that getting things just right required some care, and we became able to maintain a certain level of quality in our products.

—Specifically, what kind of care are we talking about here? Is it something that your workers, with their experience in exterior decor manufacturing, were capable of, or something that had to be left up to the designer’s judgment?

Ms. Oda: It comes down to experience. We quantify things that can be quantified, like our formulas and the ratio of materials, and our workers make adjustments as necessary. Through experimentation, we’ve learned what things influence color, we’ve realized that if we adjust this value it affects the amount of fading, and so on.

Mr. Hori: We’ve ended up with pure white products, or too much unevenness in the patterns, but we’ve moved past that. Through continuous experimentation and review of our process, we’ve been able to keep Solido at the “just right” level as a product.

—I see. Anyone can relate to the idea that a more natural look is best, or that unevenness and distortion are good things. However, to actually produce a good product, you can’t just leave it up to fate, you actually have to go through a lot of trial and error to achieve the result you want. If you don’t design it properly, you’ll end up with a poor quality product, or what you’re trying to do will be too obvious.

That’s where Solido really excels, and I think it’s something that would be quite difficult for other companies to imitate. Getting things “just right” requires a lot of knowledge.

—Listening to everything you’ve said has given me a sense of the breadth of the possibility for collaboration. I can easily picture your product being used in art museums, tea rooms, and studios, and I can’t wait to see what people do with it. Lastly, could I ask you about your future plans for Solido?

Ms. Oda: It’s currently only available through agents, but we’ve had comments from individuals who have seen it on social media, asking where they can buy it. It currently lacks the features required for retail sale, so unfortunately we’re not able to respond to these requests at this point. But I’d like to give ordinary users the chance to get their hands on it.

We also have international sales channels, so I’d like for us to expand into North America, other Asian countries, and Russia.

Mr. Hori: Construction materials like siding board gradually decrease in value with time. However, one of Solido’s advantages is its aging.

The value of the material might become even more apparent with time, or it could create added value by continuing the story of the business using it. We want to have fun with such things while working with designers who share our beliefs to enhance Solido’s value and share it with more and more people.

(Written by Yoshie Kitagawa, photography by Hanako Kimura* *Note: Photographs labeled “reference photo” provided by KMEW.)

* Solido samples are available at MTRL Kyoto.

*You can view the Solido catalog online!

>>> typeM

>>> typeF

Interviewees

Masanori Hori (Design Group, Product Planning Department, KMEW Co., Ltd.)

Keiko Oda (Strategic Planning Group, Strategic Planning Department, KMEW Co., Ltd.)

MTRL KYOTO・FabCafe Kyoto Manager

Kosuke Kinoshita

After graduating from Kyoto Prefectural University, I worked as a manager at the cafe “neutron” · art gallery “neutron tokyo”. School utilization facility “IID Setagaya Monozukuri School” is responsible for creators’ workshops and exhibitions, and collaboration with companies, schools and local governments. Joined Loftwork 2015 in charge of “MATERIAL KYOTO” to open from the fall of 2015. Under the motto of “creating an open and realistic place”, he is actively working as an “intermediary” promoting exchanges and emergence beyond regions and specialized fields.

A note from the editor (Kinoshita of MTRL Kyoto)

How did you enjoy the second edition of Dive into Material? Cement is a material that can be found all around us. When I discovered Solido, I realized that my preconceptions about cement as a functional, cost-effective material for general use, yet synonymous with homogeneity and somehow lacking in meaning, was wrong. Cement is made using natural materials, can be reused, and when design techniques are properly employed in the production method, it has a wonderfully unique texture. Solido combines the features of a mass-produced industrial product with a spice of originality, and has expanded beyond its original purpose as a construction material, gaining popularity among antiques fans and DIY lovers. This new material is loved by discerning customers who appreciate the changes wrought by time and the beauty of variation, and I feel that it establishes a new criteria for value separate from functionality and cost: good aging.

Recommended Articles

Recent Articles

-

Interview

Creating the “New Normal” for the Future: What is the “Complexity” Necessary for Co-Creation Between Academia and Industry? An Interview with Professor Kouta Minamizawa (Part Two)

-

Exploring New Realms of Design with Academia – An interview with Professor Kouta Minamizawa about the potential of co-creation projects with Academia -(Part One)

-

REPORT:School of Fashion Futures