- Event Report

Material Meetup Tokyo vol. 03 “Structure and strength” – Report

The theme this time was "structure and strength". Here are some details about what happened the day of the event.

Event summary: Material Meetup Tokyo vol. 03 “Structure and strength”

What is Material Meetup Tokyo?

Material Meetup Tokyo is an event where manufactures as the vendors, and creators and designers as the makers, come together to look for the charm that encompasses materials by “extracting the charm of the materials”. By learning about the charms inherent to materials such as the background that led to their creation, or the details and characteristics that led to the form they have now taken, while actually coming in contact with those materials, we look for different purposes for them than up to now, and think about new values they hold.

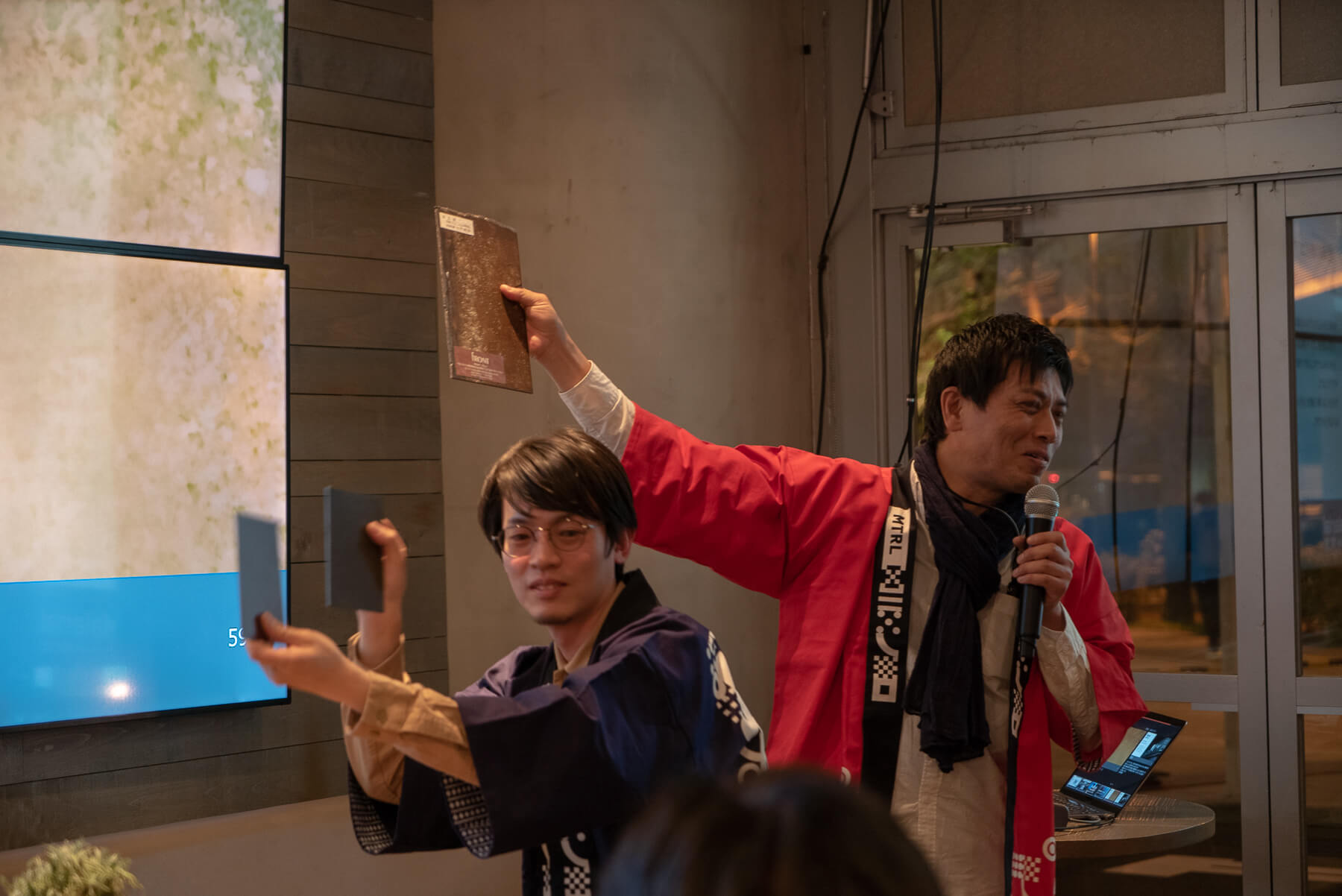

The event’s organizers are MTRL Tokyo producer Kazuya Ohara, and Fushigi design representative Keita Akiyama.

A summary of the presenters and talk details at this event

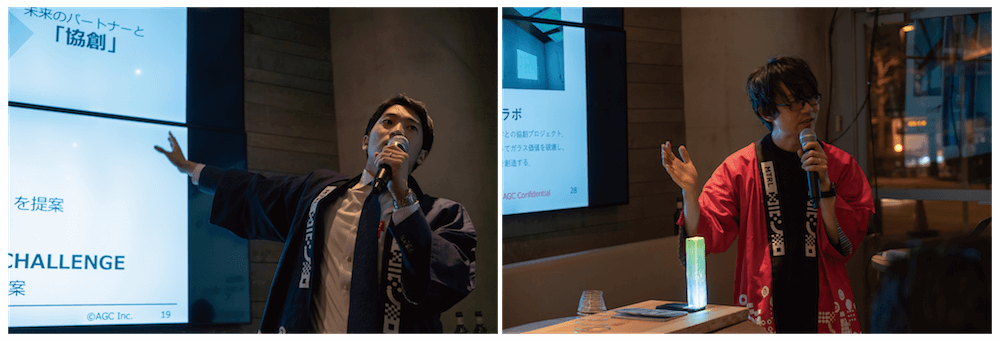

AGC Inc.’s jointly developed project “Silica”

AGC Inc.’s jointly developed project “Silica”

The creator collaboration exhibit “Animated”

Yuki Kitano, and Yohei Kawai

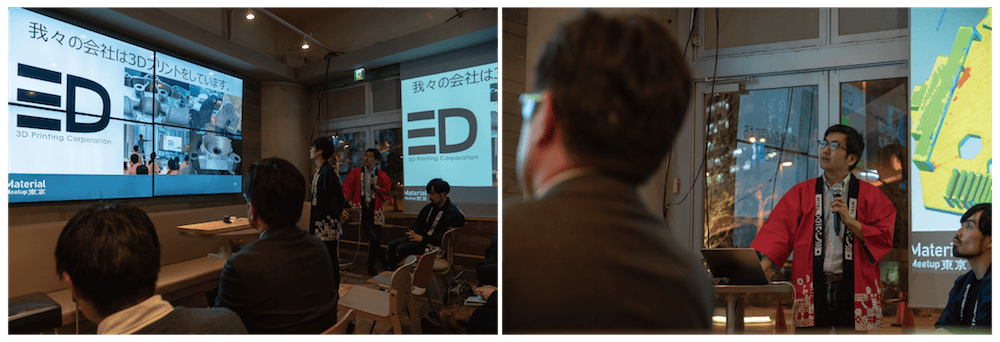

Supporting R&D for the manufacturing industry via “DfAM”, a new design method that maximizes the usage of 3D printing

Supporting R&D for the manufacturing industry via “DfAM”, a new design method that maximizes the usage of 3D printing

3D Printing Corporation’s Yoichiro Koga

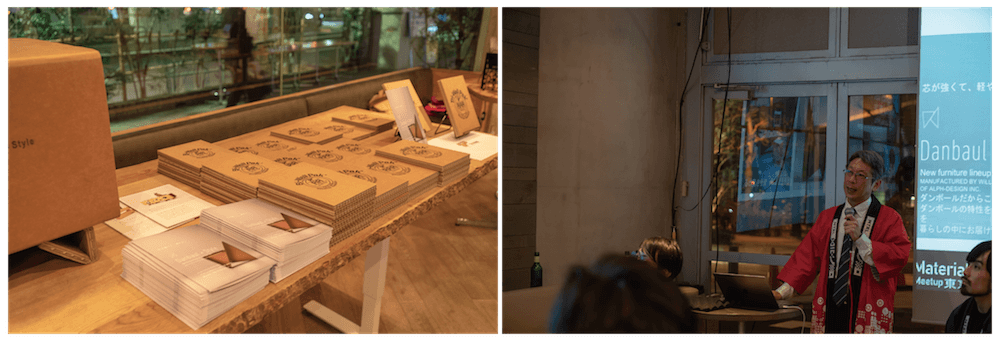

Reinforced cardboard that is No. 1 in the industrial weight packing world

Reinforced cardboard that is No. 1 in the industrial weight packing world

Tri-Wall by Tri-Wall Japan Co., Ltd.

Mitsuhiro Okamoto

Weathered steel that converts rust into beautiful designs

Weathered steel that converts rust into beautiful designs

“ARTSTEEL” by Front

Masayuki Fuji

Talk details

Each presenter introduced each of the materials. Afterwards, manufactures, sponsors, and creators as a group thought about a given material’s concept, its particulars, and its possibilities in the future.

[ Case: 01 ] “Tri-Wall” for various solutions

“Tri-Wall” is the world’s strongest industrial weight packing material. This cardboard was originally developed for the transport of military supplies. It is both very strong and yet it has a high environmental performance by making use of a material that can be continuously produced. By making use of those appealing traits, it has changed into various forms to respond to the needs of customers and the market.

“Danbaul × Style” has developed things such as shelves and chairs that use Tri-Wall by making use of its characteristic light weight and strength, and this furniture brand makes items that can easily be assembled without the use of special tools. Additionally, they have developed “Altana×Style” products that use Tri-Wall in caskets, which proposes a way to make funerals more environmentally friendly while being able to leave behind and convey one’s sentiments about the diversification of the modern age. Furthermore, by painting them or printing on them by making use of its traits, this may also be used as an art piece. The presenter Mr. Okamoto asked, “What do you like about Tri-Wall?” and the answer was, “It’s creative aspect.”

[ Case: 02 ] “MarkTwo” taking advantage of the 4th industrial revolution

By using carbon material, the 3D printer “MarkTwo” makes it possible to produce items that are light and have the same strength as metal. Up to now, the prototype that only made use of iron and steel produced items that were close to or on the same level of strength and high precision as iron and steel. The price is set at an unprecedented ¥2 million per machine, so this 3D printer is also rather cheap. (Even if this is considered “cheap”, the price is still rather steep…) The 3D printer is said to be one technology of the 4th industrial revolution. Just as the Internet that represented the 3rd industrial revolution rapidly developed over 10 years, 3D printers will also continue to develop even more. But what must happen to be on the same level as the Internet revolution? Mr. Koga said, “In recent years, all kinds of things have been made as part of infrastructure. In the middle of that, I have wondered if the next thing to be made as part of infrastructure would be “manufacturing power”. And so, this project is the realization of that.” After 10 years, each home would have its own 3D printer, allowing for the personal creation of all kinds of things in the home, which would perhaps make living self-sufficiently commonplace.

[ Case: 03 ] Uncompromising steel beauty: “ARTSTEEL”

“ARTSTEEL” controls rust with rust to produce weathered steel to convert it into an extremely beautiful material by enhancing its design via a craftsman’s skill of using that rust. In addition to that material being used on walls at Kichijoji Station in Tokyo, it is also being used in a variety of other products such as gates, fences, signs, front doors, tables, and more. Rust normally has negative connotations attached to it. However, things that have a vintage feeling to them or objects with imperfections have become appreciated in recent years, and items that are compatible with natural materials have been preferred, so the demands in the market have changed. By flexibly responding to those changes in the market and being very particular about beauty, ARTSTEEL has been praised for its beauty because it is rusty.

[ Case: 04 ] The creation of new values: Jointly developed project “Silica”

“Animated” is an exhibit thought up by AGC Inc. that puts into practice the concept of joint developments. This exhibit produces items that defy conventional wisdom about glass. For example, there are mysterious and delicate glass items that almost seem like they are alive such as “revolving glass”, “dancing glass”, and “wandering glass”. The mystical charm hidden inside of them makes you forget about the passage of time while looking at them. Originally, AGC that has conducted the in-house initiative of personally expressing “self-sufficiency” launched the jointly developed project “Silica” in 2018. And the “Animated” exhibit was the result of that project collaborating with creators. By collaborating with the fields of art and design, this exhibit presents items that challenged new ways to use glass. By creating an appeal and value for glass that differs from what has been done up to now, the aim has been for the creation of new business opportunities. Mr. Kawai remarked, “I want to create glass that comforts people.” It would seem that glass as a material has all kinds of possibilities that still cannot be seen in its transparent interior.

Conclusion

We are so thankful that this Meetup was packed once again. The materials presented at this event have all altered structure and strength, or have otherwise altered perceptions, leading to materials that are even more fascinating. Instead of sticking to a fixed concept, they have flexibly responded to the demands of the market.

Material Meetups are periodically hosted in Tokyo and Kyoto. Look forward to the next one!

Recent Articles

-

Interview

Creating the “New Normal” for the Future: What is the “Complexity” Necessary for Co-Creation Between Academia and Industry? An Interview with Professor Kouta Minamizawa (Part Two)

-

Exploring New Realms of Design with Academia – An interview with Professor Kouta Minamizawa about the potential of co-creation projects with Academia -(Part One)

-

REPORT:School of Fashion Futures