- Event Report

Material Meetup TOKYO Vol.8“The future made possible by actuators/sensors” event report

With “materials” as its core theme, ever popular Material Meetup TOKYO showcases the amazingness of various materials beyond what catalogues can illustrate, and functions as a space where new collaborations come to fruition.

The Vol.8 meeting held on 1/22/2020 (Weds) revolved around the theme of “the future made possible by actuators/sensors.” The words “actuator” and “sensor” inevitably give the impression of complicated electronics and engineering. Yet the presentation surprisingly touched on familiar topics such as fashion.

The meetup served to help participants directly experience the fact that leading edge technologies which are in themselves new types of “materials” are already improving our daily lives.

Event Summary: Material Meetup TOKYO Vol.8 “The future made possible by actuators/sensors”

“Next generation rubber that moves from electricity: e-Rubber” TOYODA GOSEI CO., LTD. Masatoshi Shimada

Mr. Shimada works for TOYODA GOSEI CO., LTD., a specialized maker of rubbers and resins that grew out of the rubber research department of world renowned automaker Toyota. Company members used their rubber and resin knowhow from many years of research to develop a new type of rubber material called “e-Rubber.” e-Rubber can become an actuator that moves from electricity, or a sensor which responds to pressure or stretching. With these functions, much is expected of the the new material’s development. It could potentially be used as the muscles or haptic sensors of next generation robots, and also could enable a new wave of audiovisual media.

Sure enough, it has a surprising texture. The “transmission of the sense of touching a water balloon” demo enabled participants to experience the feel of the material, which is very difficult to describe but could be described as “squishy” or “raw and alive.”

e-Rubber is still in the development and improvement stage, but its real world use is already being put to the test. The first product made of e-Rubber is a coronary artery bypass operation simulator which came out in October 2019. Up until now, the most common way of doing this operation has involved momentarily stopping the patient’s heartbeat. That being said, we know that doing it without stopping the heart puts less burden on the patient’s body. For surgeons to gain the skills necessary to do this, they need a simulator which is as close to the real thing as possible.

The idea of using e-Rubber as a sensor is also expanding. Adding e-Rubber to a robot’s hand could give the robot a sense of touch. For example, a robot with e-Rubber on its fingertips could instantaneously determine whether an egg is soft or hard, and handle the egg with the correct amount of pressure. There was discussion about how robots up til now have lacked a sense of touch that would enable them to determine the softness of items and hold them gently when necessary.

Equipping e-Rubber to robots’ fingertips instantly upgrades the potential of robot development. Mr. Shimada said he would like to “create a market for new developments not only in robotics and IoT, but also in medical treatments and nursing as well as the automobile field where the company began.”

“Future living with E-textiles” Surface&Architecture Tetsuya Tsuchida

UX designer Mr. Tsuchida did a presentation on E-textiles, focusing on the “SWIPE APRON” which marked the beginning of his career. SWIPE APRON was made so that people could cook while viewing recipes on their tablet, without touching the screen with wet hands.

All you have to do is make sure your tablet and the apron are connected, and then you can scroll on your tablet by swiping over the apron’s pocket area. This led to other deviations, and his continued efforts on the project series led to his acquaintance with the world of E-textiles.

SWIPE APRON: https://www.youtube.com/watch?v=yNoWRXsTb34

E-textiles are fabrics which conduct electricity. Many types are being developed, including conductive threads, cloths, velcros, knitted wiring. These materials are made into items including wearables like jackets. While fabrics have been integral to human lifestyles for over 2000 years, digital devices are still in the development stage, so they haven’t quite become something that we expect to touch with our skin every single day. Mr. Tsuchida proposed that “E-textiles which have the good qualities of fabrics while being highly compatible with digital devices could very well come to close the gap between humans and devices.”

“The smart apparel solutions brought by ‘e-skin’” Xenoma Inc. Ichiro Amimori

Although the movement to utilize sensors in healthcare has experienced a great surge in the technology industry, there have been countless discussions about the idea that wearable devices are stressful for people who are not accustomed to wearing wrist watches.

“e-skin Sleep & Lounge,” winner of the CES 2020 Innovation Award, is a product which offers one solution to that issue. The latest in the “e-skin” apparel series, it’s a loungewear set that can be worn daily, even by older folks.

It looks and feels just like the ordinary loungewear we’re all used to. The stiffness and unnatural feeling of digital devices are not present. Responsible for the e-skin smart apparel line’s development is Xenoma, the company whose elastic wiring and coordinated sensor field technologies enabled their garments to be worn stress-free while monitoring things like sleep quality and accidental falls. These wearable devices have become a hot topic.

Continued use of smart apparel products like the “e-skin Sleep & Lounge” line which presents the feasibility of “true wearables” could help us to accumulate big data on human healthcare which would enable us to predict illnesses earlier than ever before.

That being said, the reality that healthy people tend to be less concerned about their own health will make it hard for such items to enable a true big data platform for healthcare. It will be necessary, therefore, to introduce features and services which benefit healthy users in their daily living. Mr. Amimori says that “e-skin could be post-AI.”

Website: https://xenoma.com/

Twitter: @Xenoma_Inc

e-skin Sleep and Lounge: https://youtu.be/m0uc8kxGSGA

“The ‘motor module ®’ born from the idea of ‘adding robot functionality to the motor itself’” Keigan Inc. Takashi Tokuda

Seeing is believing, and it was Tokuda-san from Keigan Inc. who demonstrated KeiganMotor’s technology. KeiganMotor is a motor module ® equipped with robot functions including sensors and a controller.

It puts a highly efficient motor, controller, wireless module, and sensors into a single device that comes with software to control everything. These features make it a groundbreaking actuator that enables easy “rapid prototyping.”

The Keigan Motor lets you make a robot with shocking ease

We tend to think of sensors and actuators as separate pieces. The idea of “putting robot functionality into the motor itself” is revelatory. It seems like an obvious solution once you see it, but it has not really been implemented up until now.

The development of digital machines with robotic elements and sensors seems like a very difficult and complicated subject, but the KeiganMotor makes it possible to create prototypes very quickly. This module is a developer’s dream in the way that it could lower the barrier to making things and speed up the product design process.

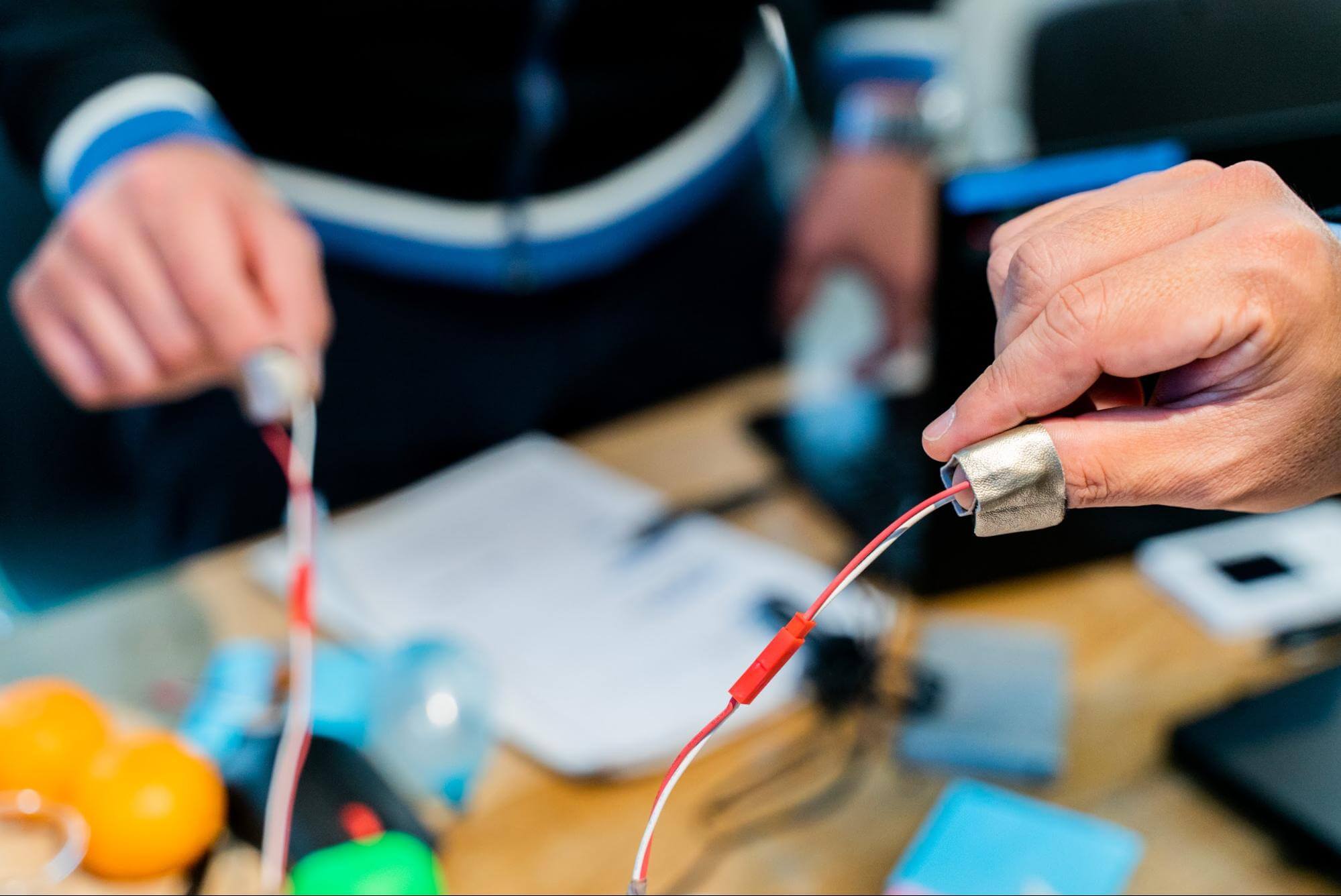

Actuators and sensors need proper functionality and output specifications to be truly useful. After the presentation and gathering, demonstrations were held at the booths of each product. Participants were extremely interested in the leading edge technologies displayed.

Showcasing information not found in catalogues and websites at a proximity even closer than an exhibition or gallery space could only be possible through Material Meetup. The meeting space was full of enthusiasm through the late hours of the evening.

Recent Articles

-

Interview

Creating the “New Normal” for the Future: What is the “Complexity” Necessary for Co-Creation Between Academia and Industry? An Interview with Professor Kouta Minamizawa (Part Two)

-

Exploring New Realms of Design with Academia – An interview with Professor Kouta Minamizawa about the potential of co-creation projects with Academia -(Part One)

-

REPORT:School of Fashion Futures